World’s largest off-grid hybrid system in the mining industry

01—

Setting the scene

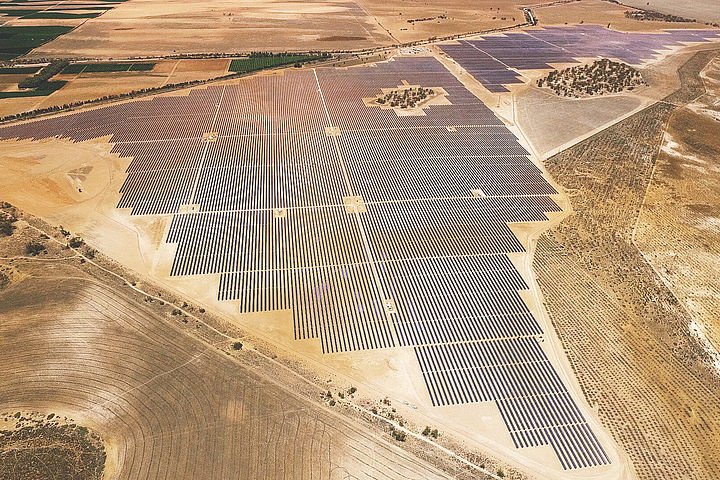

Located in remote West Mali, a stone’s throw from the Senegal border, the B2Gold Fekola mine is totally reliant on onsite generated electricity for its 24-hour operations. There is no access to the public electricity grid and the gold mine has been using a large thermal generation plant that requires heavy fuel oil (HFO) to power its eight generators.

B2Gold was keen to reduce its reliance on HFO at the Fekola mine – the largest in its portfolio - and to find a more economic, environmentally-friendly and less carbon intensive way of delivering secure and stable electricity supplies.

Baywa r.e. worked with Hamburg based consultancy Suntrace GmbH to develop a feasibility study to demonstrate how a hybrid energy solution could work. The study showed that by combining solar PV and battery storage with the existing conventional generation, the hybrid system could deliver exactly what was required at the flagship site.

The project was quickly approved for implementation by B2Gold, and construction and commissioning were completed in a first phase in April 2021 and was finally in summer 2021. The project has been implemented in a joint team effort of the three companies and various suppliers.

02—

Meeting the Challenges

To be successful, the hybrid approach needed to ensure a reliable electricity supply day and night and in an operation format that required little intervention from site operatives to manage the increased complexity after adding the new technologies.

The solution conceptualised by BayWa r.e. includes a smart energy management system that monitors the operation of both the existing thermal plant and the PV installation and uses the battery as flexible and dispatchable unit to absorb or discharge power when required. This way efficient and reliable operation of the entire system can be ensured.

The system employs satellite-based forecasting and draws on intelligence from a site camera that records cloud patterns when it is a cloudy day, and informs the thermal plant team when an additional generator may need to be fired up in anticipation of a decrease in solar generation.

BayWa r.e and its Consultancy subsidiary Renerco provided a full range of services for engineering, procurement, construction and commissioning of the system. In particular, our expertise was required to ensure the optimal integration with the existing thermal plant by sourcing a suitable battery storage and energy management system and ensuring the control concept would be implemented as it was developed in the early phases of the project.

The project is a great example of collaboration and team working across all the companies, enabling each to bring its own expertise and experience into play for the benefit of the client.

03—

The result

The project allows half of the HFO generators to be shut down during daylight operations, and the remaining ones to reduce their output significantly. The energy management system assures that safe and reliable power will continue to be delivered, 24/7. In first tests during the summer months 2021, we could even shut down four of six generators on very sunny days. A result, that even exceeds our expectations and further increases the overall efficiency of the system.

The 15.4MW battery adds stability and robustness to the system, which allows up to 75% of the mine’s electricity demand to be produced by the solar installation during the day. Now fully operational, the hybrid energy system saves around 13 million litres of HFO a year and deliver a reduction in CO2 emissions of 39,000 tonnes a year!

The project is an exciting development and evidence of the real potential offered by hybrid projects in West Africa and for large-scale offgrid customers.

Suntrace and BayWa r.e. have played a vital role in our work towards more sustainable production at Fekola. The implementation of a solar-battery hybrid system was an obvious choice to help achieve not only environmental credentials, but also economic viability.